PVC waterstops (Polyvinyl Chloride) are used in construction projects to provide a watertight seal and prevent the passage of water through joints or cracks in concrete structures. They are produced a durable and flexible thermoplastic polymer.

Excellent water resistance

Chemical resistance

Durability and longevity

Flexibility and adaptability

Easy installation

Versatile applications

Cost-effective

Compatibility with different construction materials

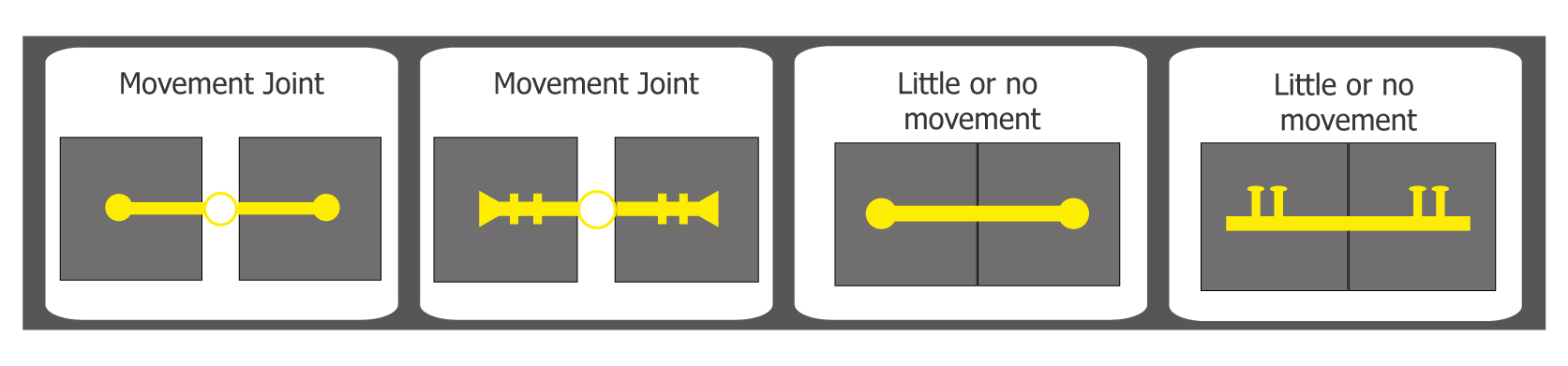

PVC waterstops have a specific profile design to enhance their effectiveness in preventing water leakage. Common profiles include ribbed, bulb, or dumbbell shapes, which create a compression seal when embedded in concrete joints.

These are engineered to possess both strength and flexibility to accommodate movement and settlement in concrete structures. They should be able to withstand hydrostatic pressure, seismic activity, and temperature variations without losing their sealing properties.

Excellent water resistance

PVC waterstops are highly effective at preventing water penetration in joints and construction seams. They create a watertight barrier that ensures long-term waterproofing and protects structures from water damage.

Chemical resistance

PVC waterstops exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents. This chemical resistance makes them suitable for applications where exposure to aggressive substances is expected, such as wastewater treatment plants, chemical storage facilities, and industrial environments.

Durability and longevity

PVC waterstops are known for their durability and long service life. They are resistant to degradation from UV radiation, ozone, and weathering, ensuring their performance in outdoor applications. PVC waterstops can withstand the effects of expansion, contraction, and joint movement over time without losing their effectiveness.

Flexibility and adaptability

PVC waterstops are highly flexible and can conform to irregular shapes and contours, allowing for easy installation in various joint configurations. They can accommodate movements in the structure caused by settlement, thermal expansion, or seismic activity, maintaining the integrity of the waterproofing system.

Easy installation

PVC waterstops are typically preformed in various shapes and sizes, making them easy to handle and install. They can be embedded in the concrete or attached to the construction joints using welding, adhesive bonding, or mechanical fastening methods. Their ease of installation saves time and labor during the construction process.

Versatile applications

PVC waterstops are suitable for a wide range of applications, including below-grade structures, water tanks, swimming pools, tunnels, dams, and hydraulic structures. They can be used in expansion joints, construction joints, pipe penetrations, and other areas where waterproofing and water containment are essential.

Cost-effective

PVC waterstops offer a cost-effective solution for waterproofing applications. Their durability, longevity, and low maintenance requirements contribute to overall cost savings over the life of the structure. PVC waterstops are often more affordable than alternative materials such as rubber or metal.

Compatibility with different construction materials

PVC waterstops can be used with various construction materials, including concrete, masonry, and steel. They provide a reliable and compatible waterproofing solution in conjunction with these materials.

Hs Code

3920.49.90.00.00

PVC waterstops are mostly used in;

Concrete structures like basements, swimming pools, and tunnels.

Civil engineering projects such as bridges, culverts, and canals.

Infrastructure projects like highways, airports, and railway stations.

Hydraulic structures like water treatment plants and reservoirs.

Industrial facilities dealing with chemicals or wastewater.

Residential and commercial buildings for waterproofing.

Retrofitting and rehabilitation projects for enhancing waterproofing.

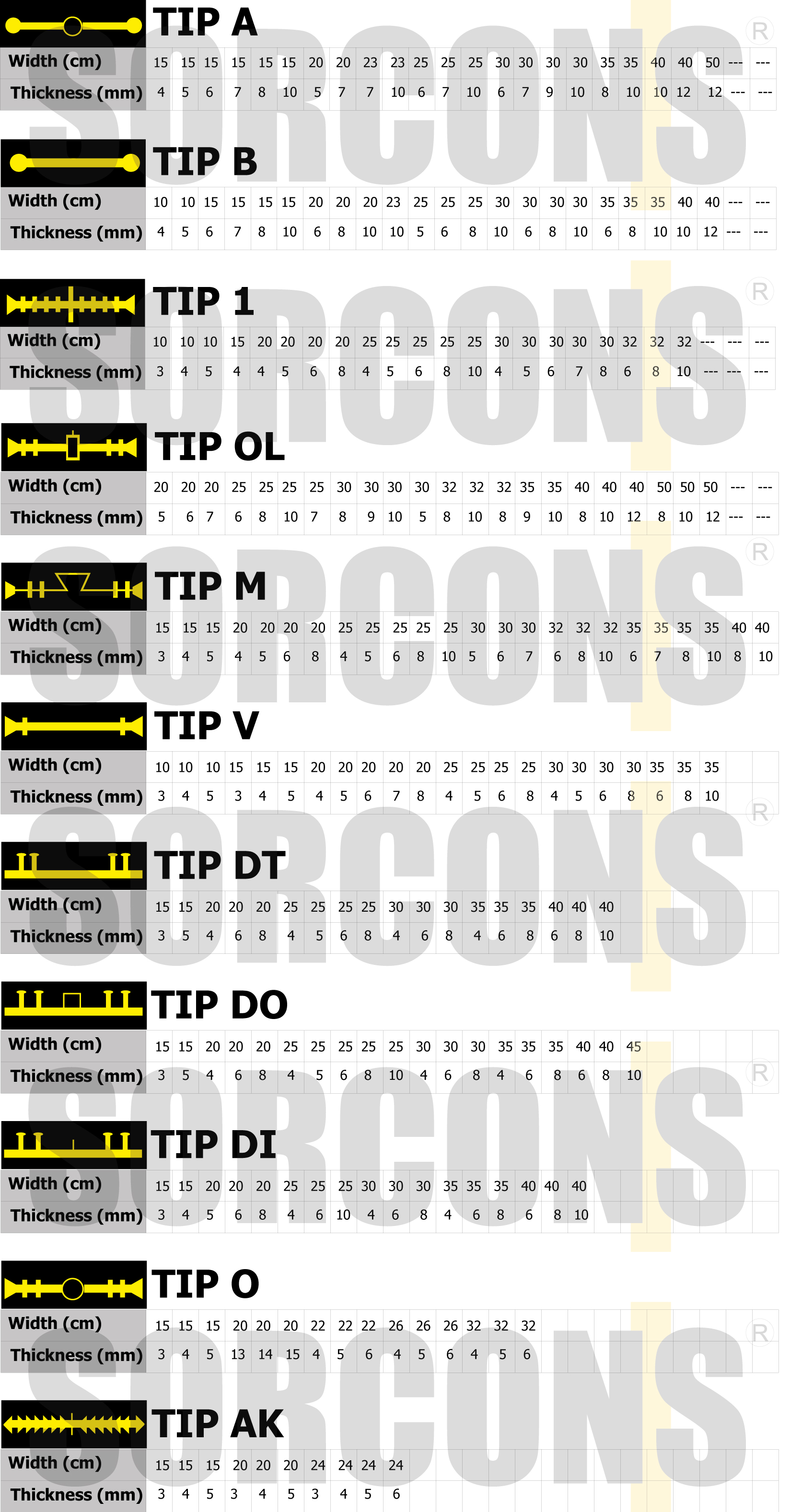

PVC waterstops are available in various shapes including straight lengths, intersections, corners and T-sections. The size and dimensions can vary depending on the application and project requirements.

| Data Type | Data Limits |

SPECIFIC GRAVITY | 1,27 ( 0,03 ) g/cm |

TENSILE STRENGHT | 20 kN |

ELONGATION RATE | %295 ort. , %225 min. |

ASH RATE | %5 ( max) according to weight |

WATER ABSORPTION RATE | %1 ( max) according to weight |

HARDNESS ASTM D 2240 | 75(±5) Shore “A” |

SERVICE TEMPERATURE | (-15 °C / +50 °C) |