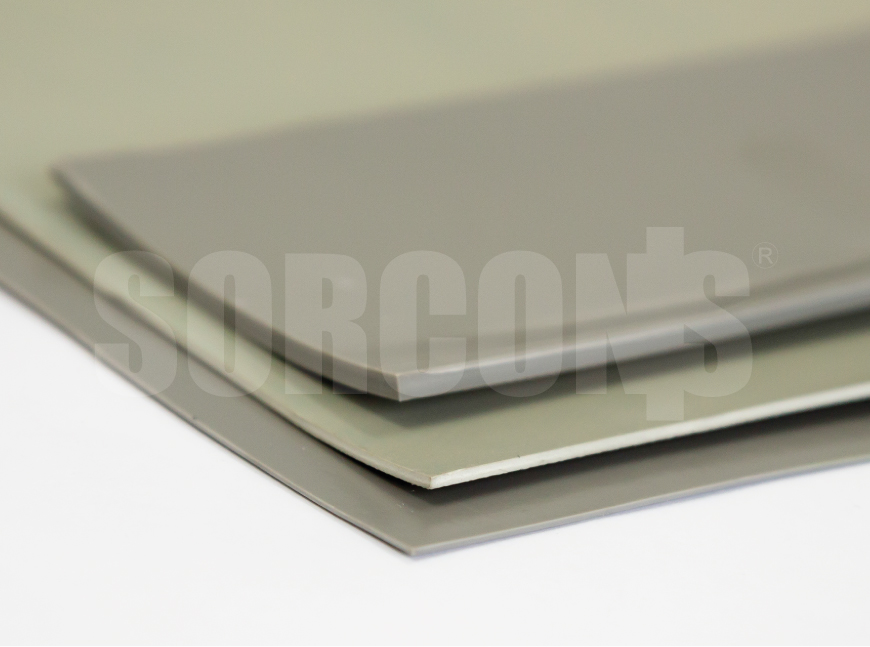

PVC (Polyvinyl Chloride) membranes are widely used in various applications, including roofing, waterproofing, and also lining systems.

They are designed to withstand exposure to the elements, including UV radiation, extreme temperatures, and chemicals.They are typically formulated with stabilizers and additives to ensure long-term durability.

PVC (Polyvinyl Chloride)

Resistant to temperatures between -40C and +70 C.

Formulated with UV stabilizers to withstand prolonged exposure to sunlight and prevent degradation over time

Offers perfect resistance to a wide range of chemicals, making them suitable for various containment applications involving hazardous substances.

It does not contain any toxic

materials. Fully environment

friendly.

Excellent Waterproofing

PVC geomembranes provide an effective barrier against water and moisture. They prevent seepage, leakage, and contamination, ensuring the integrity and protection of structures and environments.

Chemical Resistance

Have good resistance to a wide range of chemicals, making them suitable for applications involving hazardous substances or aggressive chemical environments.

Durability

Known for their durability and long lifespan. They can withstand harsh weather conditions, UV exposure, and mechanical stress without significant degradation.

Flexibility

PVC geomembranes are highly flexible, allowing them to conform to irregular surfaces and accommodate ground movements. This flexibility makes them suitable for various installation conditions.

Weldability

Can be heat-welded at the seams to create strong and watertight joints. This seamless installation method ensures the continuity of the liner and minimizes the risk of leaks.

Versatility

PVC geomembranes can be used in a wide range of applications, including landfills, ponds, mining operations, canals, agricultural systems, and more. Their versatility allows for customization and adaptation to different project requirements.

Cost-Effectiveness

PVC geomembranes often offer a cost-effective solution compared to alternative materials or methods. They are relatively affordable, easy to install, and require minimal maintenance over their lifespan.

Environmental Protection

PVC geomembranes help prevent the migration of contaminants, such as chemicals or waste materials, into the soil and groundwater. This protects the environment and reduces the risk of pollution.

Aesthetics

PVC geomembranes are available in various colors and textures, allowing for aesthetic customization in applications such as decorative ponds or swimming pool liners.

HS Code 4002.70.00.00.00 |

|---|

Roofing

Provides waterproofing for flat or low-slope roofs.

Waterproofing

Prevents water penetration in structures like basements, tunnels, and parking decks.

Pond Liners

Prevents water seepage in ponds and water containment systems.

Tank Liners

Provides corrosion resistance and prevents leaks in storage tanks.

Tensile Structures

Used in tensioned fabric structures for innovative designs.

Agriculture

Protects agricultural structures like greenhouses and silage pits.

Swimming Pool Liners

Provides durable and waterproof surfaces for swimming pools.

Gas and Oil Industry

Provides secondary containment in oil and fuel storage and drilling waste systems.

Pond and Lagoon Liners

Maintains integrity and prevents seepage in water containment systems

| Data Type | Data Limits | Standard of Testing |

| Thickness | 1,00 mm minimum | DIN 53370 |

| Tensile Strenght | 15 N/mm² minimum | DIN 53455 |

| Elongation at Break | %250 minimum | DIN 53455 |

| Break Resistance at 20% Unit Elongation | 2,5 N/mm² | DIN 53454 |

| Spread Tear Strenght | 100 N/mm minimum | DIN 53363 |

Water Pressure Strenght | At 10 Bar For 10 Hours | DIN 16726 |

Welded Joint Strenght | 13,5 N/mm² minimum | DIN 16726 |

Dimensional Stability After Rapid Aging | ±%2 maksimum | DIN 16726 |

| Material Properties During and After 80ºC Storage | DIN 16726 | |

a. Overview | No Bubbles | DIN 16726 |

| b. Dimensional stability, longitudinal and transverse | <-%3 | DIN 16726 |

| c. Change in tensile strength, longitudinal and transverse | <±%20 | DIN 16726 |

| d. Change in Elongation at break, longitudinal and transverse | <±%20 | DIN 16726 |

| e. Folding At -20 ºC | No Cracks | DIN 16726 |

| Changes After Stored in Acid And/Or Alcaline Solutions | DIN 16726 | |

| a. Change in tensile strength, longitudinal and transverse | <±%20 | DIN 16726 |

| b. Change in Elongation Per Unit | 100 N/mm minimum | DIN 53363 |

| c. Folding at -20 ºC | No Cracks | DIN 53363 |

| Shear Resistance, Bitumen Annex | 100 N / 50 mm | DIN 16726 |

| Punching Test Behaviours | No Punching at 750mm Height | DIN 16726 |

| Water Absorption | Max. %1 | DIN 53495 |