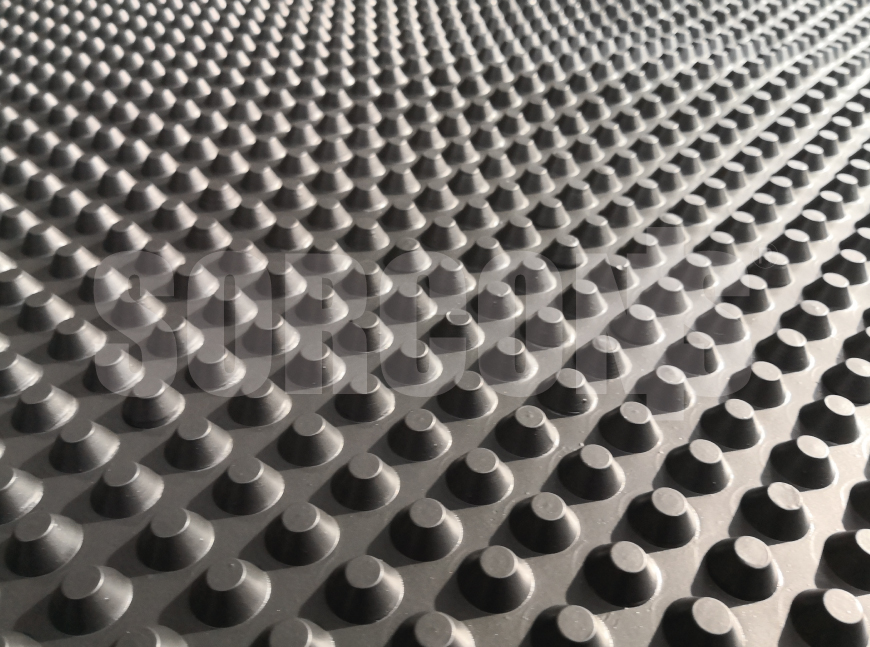

HDPE (High Density Polyethylene) is a specialized dimpled foundation membrane that features a unique dimpled design.

Dimpled drainage membrane effectively protects structures against water intrusion. The dimpled design enhances drainage capacity by providing a clear path for water to flow away from the structure, preventing water buildup and potential damage.

It has a unique superseal dimpled membrane pattern that creates a continuous drainage space. These dimples create an air gap between the dimpled membrane subfloor and the foundation surface, facilitating the quick and efficient flow of water away from the structure.

High Density Polyethylene

(HDPE)

Creates an ideal drainage

layer and provides rear ventilation of the foundation walls.

Durable against mechanical

damage and harmful effects

of tree roots and shrubs.

Helps to protect ceiling from

moisture.

It can also be used as heat

and sound insulation.

It does not contain any toxic

materials. Fully environment

friendly.

Material

HDPE (High-Density Polyethylene)

Dimple Design

The dimpled waterproofing membrane features a dimpled pattern on one side, typically in a cylindrical shape. These dimples create an air gap between the membrane and the underlying surface, promoting water drainage and providing a pathway for moisture to move away from the structure.

Water Permeability

The dimples on the HDPE dimpled membrane allow water to flow freely, providing effective drainage and preventing hydrostatic pressure buildup against the structure.

Load-Bearing Capacity

HDPE dimpled waterproofing membrane is designed to withstand the weight and pressure exerted by the surrounding soil or other construction materials. The load-bearing capacity can vary based on the thickness of the membrane.

Chemical Resistance

HDPE superseal dimpled membrane is known for its excellent resistance to various chemicals, making it suitable for applications where exposure to contaminants or aggressive substances may occur.

Installation

HDPE dimple board membrane is typically installed with the dimpled side facing the substrate or foundation wall. Dimpled wall membrane can be mechanically fastened or simply placed against the surface, depending on the specific installation requirements and conditions.

Thickness and Weight

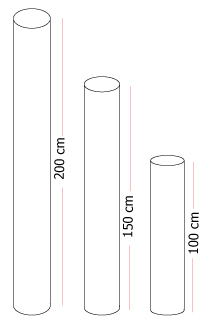

We can produce waterproof dimpled membranes in 3 types of thicknesses and weights, as given below.

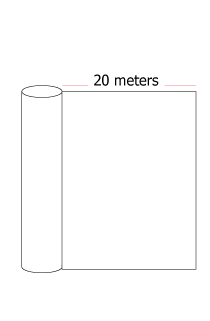

Roll Dimensions

HS Code 3921.90.60.00.11

|

|---|

Dimpled membranes are used in various construction and civil engineering applications where waterproofing, drainage, and moisture management are important. Here are some common applications of dimpled membranes:

Foundation Waterproofing

Dimpled membranes are often used as a protective layer against moisture intrusion in below-grade foundation walls. They create an air gap between the membrane and the wall, allowing water to drain away while providing a barrier against water penetration.

Basement Waterproofing

Dimpled membranes are commonly employed in basements and crawl spaces to prevent water infiltration and dampness. They can be applied to interior or exterior basement walls to provide a drainage pathway for water and protect the structure from moisture-related issues.

Retaining Walls

Dimpled membranes are utilized in retaining wall systems to manage hydrostatic pressure and prevent water buildup behind the walls. By providing an effective drainage layer, they help reduce the risk of wall failure and improve the overall stability of the structure.

Plaza Decks and Green Roofs

Dimpled membranes are employed in plaza decks and green roofs to enhance waterproofing and drainage performance. They create a separation layer between the roof structure and the overlying soil or vegetation, allowing water to drain away while protecting the underlying components.

Landscaping and Gardens

Dimpled membranes are used in various landscaping applications, such as beneath walkways, patios, or garden beds. They provide a protective barrier against water infiltration, minimize soil erosion, and facilitate proper drainage.

Subgrade Drainage

Dimpled membranes can be installed horizontally below ground surfaces, such as roads, parking lots, and athletic fields, to promote efficient subgrade drainage. They help prevent waterlogging and improve the stability of the surface.

Tunnels and Underground Structures

Dimpled membranes are employed in tunnel construction and underground structures to manage groundwater and prevent water seepage. They provide an effective drainage system to control water flow and protect the structural integrity.

| Data Type | Standart of Testing | Unit | Tolerance | SDM 400 | SDM 500 | SDM 600 |

| Material |

| High Density Polyethylene HDPE | High Density Polyethylene HDPE | High Density Polyethylene HDPE | ||

| Roll Lenght | CE Standard EN 1848-2 | Meter | (+-) 2,5% | 20 | 20 | 20 |

| Roll Height | CE Standard EN 1848-2 | cm | (+-) 0,5% | 100 cm - 150 cm -200 cm | 100 cm - 150 cm -200 cm | 100 cm - 150 cm -200 cm |

| Area Weight | CE Standard EN 1849-2 | g/m² | (+-) 6% | 400 | 500 | 600 |

| Thickness | CE Standard EN 1849-2 | mm | (+-) 0,02% | 0,4 | 0,5 | 0,6 |

Number of Stats | TS13721 | n/m² | >1800 | >1800 | >1800 | |

Resistance to Pressure | CE Standard TS EN 826 | kn/m² | 150 | 200 | 250 | |

Resistance to Tearing with Sharp Objects | CE Standard EN 12310-1 | N | (+-) 30% | 180/200 | 200/240 | 220/260 |

| Dimple Height | mm | 8 | 8 | 8 | ||

Water Resistance Capability | CE Standard EN 1928 | 60 kPa | Passed | Passed | Passed | |

Temperature Resistance | CE Standard EN 1876-1 | °C | min -30° to max +80° | Passed | Passed | Passed |

| Color | Black (Dark Grey) | Black (Dark Grey) | Black (Dark Grey) | |||

Hazardous Chemicals | EN 1397+A1 | Non Toxic | Non Toxic | Non Toxic | ||

| Guarantee | 20 Years | 20 Years | 20 Years | |||

| Pallet Units | 20 Rolls for Each Pallet | 20 Rolls for Each Pallet | 16 Rolls for Each Pallet |